Company Profile: Charltons is a family run business and has manufactured timber products for over 110 years at their sawmills near Frome in Somerset.

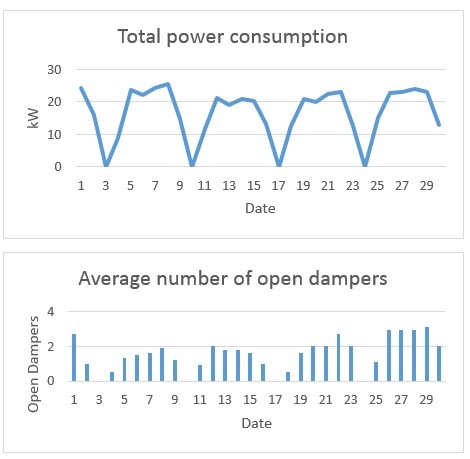

Inteliair Installation: When we were asked by the Charltons Group to look at how the efficiency of the wood waste extraction system serving their main production workshop could be improved it was clear from the outset that the Inteliair system was the answer. With a total of eighteen machines connected to the main extraction system each fitted with multiple extract points yet only 50% of those machines at most in use at any given time through the implementation of the Inteliair system it would be possible to both increase the extraction performance at the machines in use and reduce the energy consumed by their 55 kW main extraction fan during the average working day. As can be seen on the graphs below downloaded from the installed Inteliair system 1-month after installation both objectives have been achieved; the power consumption has been reduced (previously the main extract fan would operate continuously at 100% capacity) and the extraction efficiency has been increased by targeting the available extraction at the positions requiring it (open dampers).